Newell Brands

Elmer's Squishies

Elmer's Squishies are a collection of craftable, colorful, customizable (and squishy!) creatures. Kids can enjoy creating 80 unique designs in a wide range of hues using nothing more than a Mystery Mold and Elmer's patented Squishy formula. With additives, Squishies can be made to be opaque, sparkly or even glow-in-the-dark!

In late 2021, Newell Brands enlisted the help of IN2 Innovation to bring their vision for Squishies to life. The challenge was to translate dozens of 2D character sketches into detailed and lively digital sculpts and from there, build production-ready CAD databases to send off to tooling (and all in just a few short weeks!)

How do you create such complex organic forms in a parametric CAD package like Solidworks? (Spoiler: You can't!)

We would need to devise a completely new software pipeline and get the team up to speed on it in record time in order to pull this off. During the course of this project I led the effort in developing this process and played a key role in getting the team up to speed with the software skills needed to complete the program successfully and on-time.

Process

In order to go from 2D sketch to a 3D character model in Solidworks we had to take a bit of a software detour! Through trial and error we were able to nail down a Rhino/Blender/PowerSurfacing workflow that yielded the results we were after.

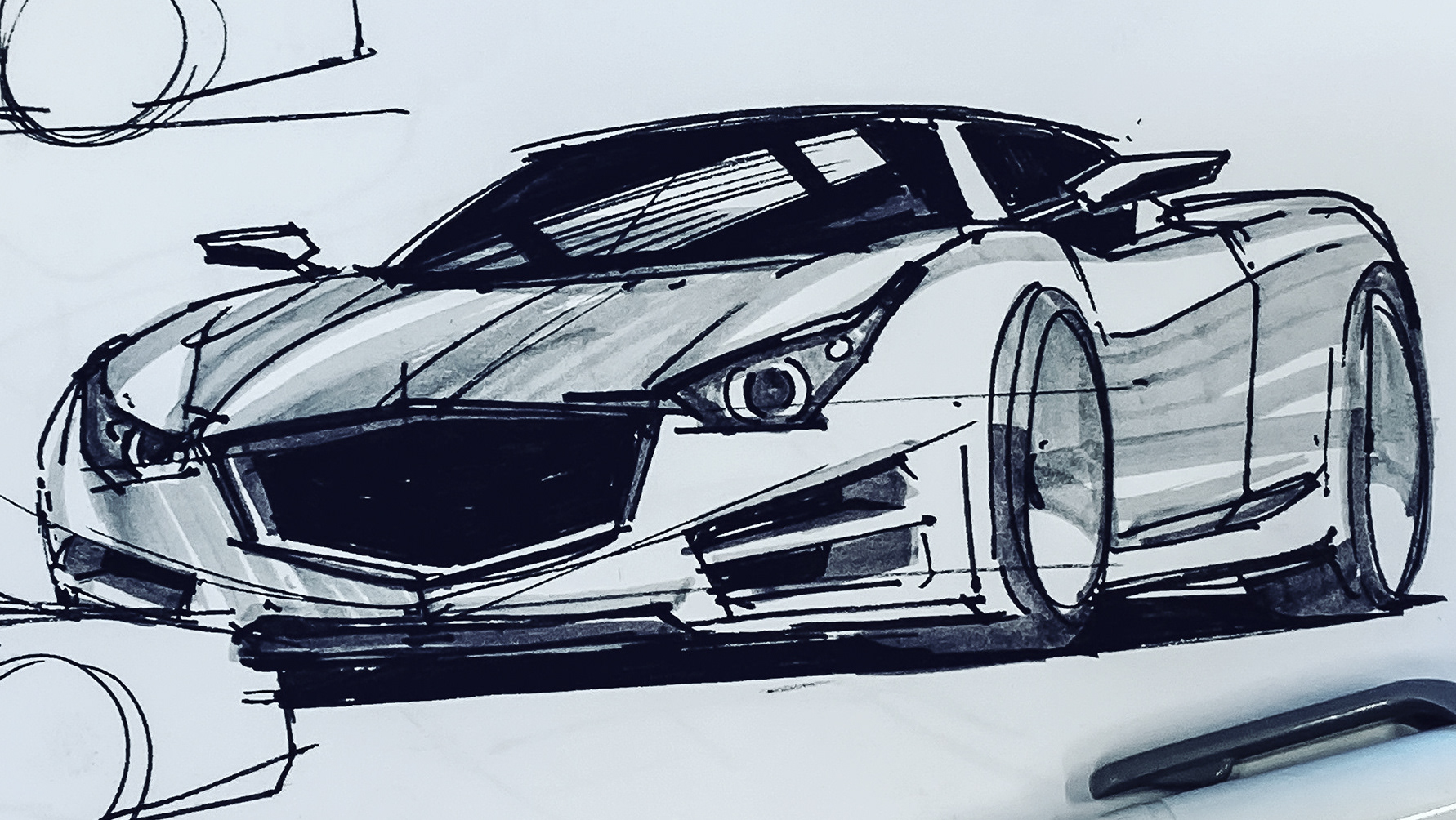

Ortho Views

Each of the character designs crafted by Newell were communicated via simple front and side orthographic views (and other detail views as needed). These were brought into Rhino to be used as a guide when building the base mesh.

Base Sub-D Mesh

Using the provided sketches, we created a sub-d mesh of the major forms of the character in Rhino, making sure to avoid making the basic masses look too blocky.

Initial Detail Sculpt

Next, we brought the base mesh into Blender and sculpted the fine details on top of that, adding or subtracting material as needed. Because this was the stage where the final shapes took form, we created a set of strict guidelines and workflows to help maintain accuracy and consistency across all 80 designs.

Print Evaluation

Once the initial sculpt had been completed, we needed to evaluate the overall read of the forms and details in hand. Often the sketches provided would "lie", forcing compromises to be made in the sculpting stage to preserve the intent of the design. This made it imperative for Newell to review the designs and sign off on the changes before prepping them for production. At the end of each sculpting phase, STLs were sent off to Newell for 3D printing.

FDM is an inherently lossy process when it comes to replicating small details. This made it the perfect benchmark for previewing the loss in detail that would naturally occur when children use the product to make Squishies for themselves.

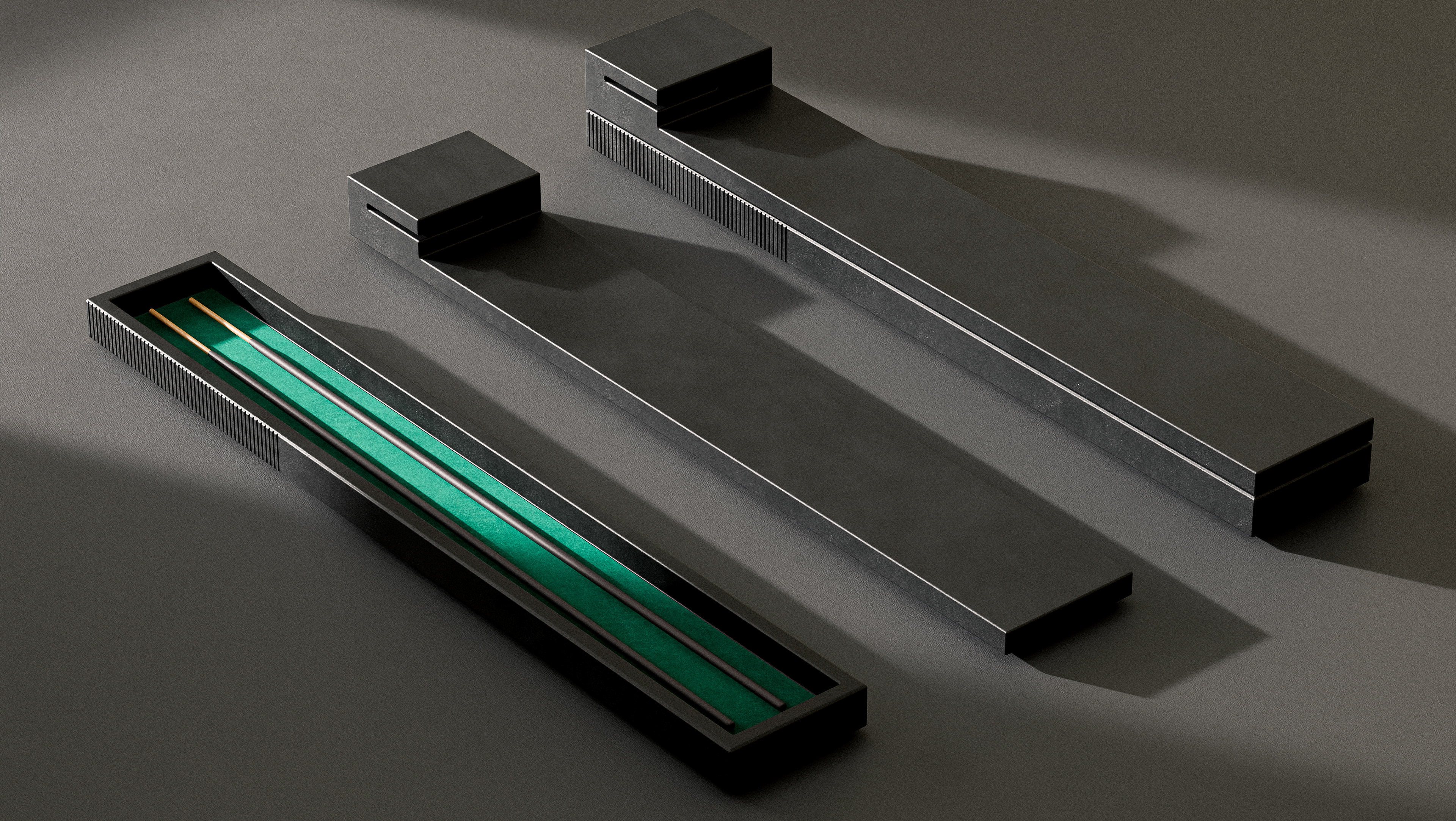

NURBs Shrinkwrap

This is the magical part! Once the characters had been printed, evaluated and all necessary revisions made, we needed to convert the poly mesh data into a CAD-friendly format. With the help of a third-party Solidworks addon called Power Surfacing, we were able to shrink-wrap the mesh with surfaces to create an airtight form. From there it was just a matter of a few Boolean operations to finalize the mold geometry!

Sculpting For Mass Production

Digital sculpting is perhaps the antithesis of CAD modeling. It is completely freeform, does whatever you tell it to no questions asked and can easily become very messy if you aren't careful! Because Blender is primarily built for entertainment-specific pipelines such as gaming and animation, it lacks many features necessary to production workflows. In order to ensure clean, properly drafted geometry ready for final mold creation we had to get creative! A custom material shader became the key to keeping a clean parting plane

With Blender's robust material node editor, I was able to develop a simple shader that allowed us to see how sculpting edits affected positive and negative draft in real time! This became critical to reducing revision passes during CAD conversion.